INTELLIGENT ROBOTICS

The research line of Intelligent Robotics investigates and applies mobile and manipulative robotics to solve real-world challenges in different sectors: industrial, critical infrastructures, defence, agriculture, etc. Our focus is especially on automating complex non-repetitive tasks, and enabling productive capabilities that people cannot perform without assistance in a safe, continuous or cost-effective manner. We design navigation, planning and control algorithms so that mobile platforms execute tasks, and robotic arms perceive and manipulate autonomously by combining control, electronics, computer vision, 2D/3D sensors and artificial intelligence. Likewise, we investigate the use of digital twins to validate solutions before robotic deployment, thereby reducing risks and time-to-market.

OUR TEAM

Our interdisciplinary team — more than ten people among permanent and affiliated staff, PhDs and masters with broad experience — works with open standards (e.g., ROS 2, Python) to ensure scalability, maintainability and compatibility with existing systems.

Adrián Salazar

Researcher in Intelligent Robotics and Computer Vision

Researcher in Intelligent Robotics and Computer Vision. He has developed his career in projects that integrate artificial intelligence in robotic platforms to improve processes in industrial and agricultural settings. Over more than eight years of work, he has worked as a robotics researcher and developer in prestigious international robotics laboratories, such as the Interaction Lab of King’s College London, the Lincoln Institute for Agri-Food Technology and the UK’s National Robotarium, participating in projects for organizations like Nokia and the University of Cambridge. Currently, Adrián participates at ITCL in intelligent robotics and computer vision initiatives, while pursuing his doctorate in robotics at the Universidad Carlos III de Madrid.

ROBOTICS CAPABILITIES

Artificial intelligence for existing machinery

We research to convert “non-intelligent” machinery into equipment capable of deciding and acting on their own. We integrate computer vision, sensors and AI control so that industrial or civil-protection arms and vehicles perceive their environment, make decisions and generalize to new situations.

Among our achievements: industrial robotic arms that distinguish different parts and place them in specific points using 2D/3D cameras and AI; assistance for snow-ploughs to stay on route even with low visibility; and robotisation of agricultural vehicles to operate autonomously on changing farms. We adapt the solution to the client’s asset — without replacing it — accelerating adoption and return; all with progressive deployment and continuous support.

Autonomous planning and navigation to automate productive tasks with mobile platforms

We research and develop algorithms for task automation that require mobile platforms with autonomous navigation in warehouses, manufacturing plants and non-urban scenarios. Our mapping, planning and mission-management algorithms allow AMRs/AGVs, quadrupeds and drones to move safely respecting established rules. Tasks such as picking, inspecting, replenishing, monitoring or delivering are supported by these technologies.

We also consider navigation with limited GPS using vision systems, with poor visibility using radar technologies, and changing-scenario operations both for single vehicles and mixed fleets.

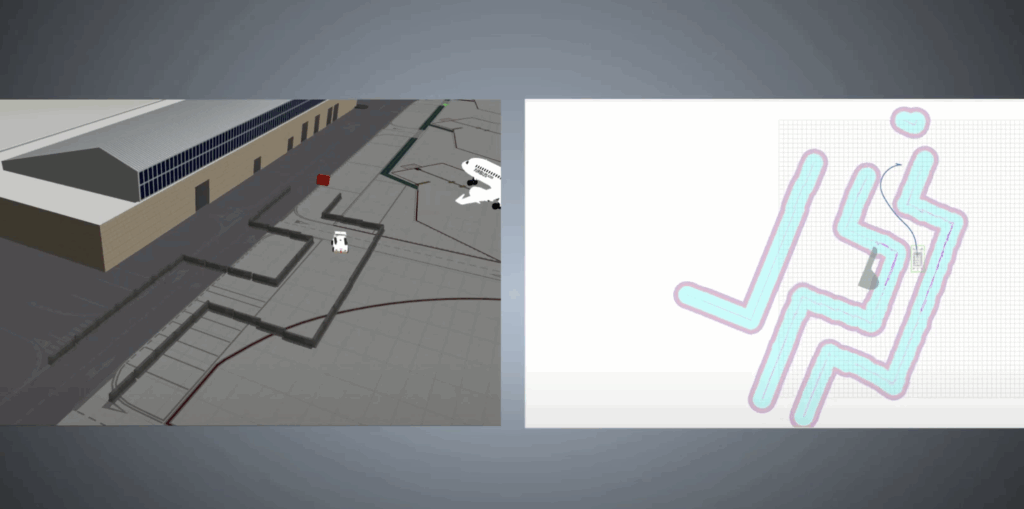

2D/3D/4D digitalization of large spaces for volumetric/temporal analysis and robotic simulation

We explore new methodologies to automate the digitalisation of large spaces in 2D, 3D and 4D (evolution in time) to analyse complex scenarios and simulate operations before executing them. We work so that terrestrial and aerial robots capture georeferenced data of a location which we convert into digital.

With that digitalisation we measure—automatically—volumes, detect changes, plan routes, test algorithms and assess the viability of robotic installations without waiting for the final robot. We also enable periodic inspections of extensive infrastructures, monitoring and temporal object location. As a reference, we digitalised the Sevilla Airport to simulate mobile platforms acting autonomously, reducing risks and startup times.

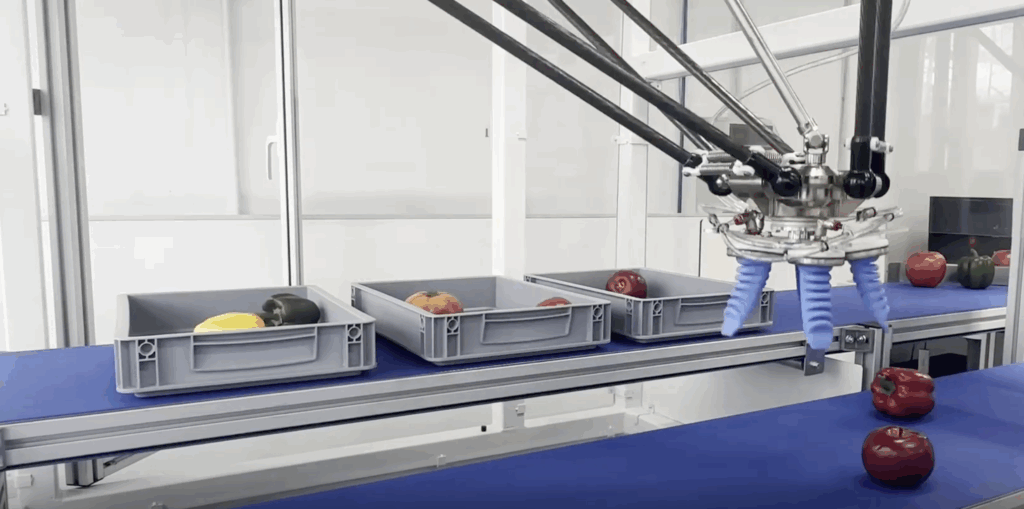

Automation via AI of manipulation and assembly processes

We deepen the creation of new methods to automate manipulation and assembly tasks where the parts vary in shape, size or position and the environments are not perfectly ordered. We combine 2D/3D vision, force sensors and artificial intelligence so that the arms know what to grasp, how to do it and where to place each object—even when the reference moves or is unstable.

We cover research ranging from placing non-uniform parts on shelves, collecting soil samples, to manipulating agricultural products of different sizes.

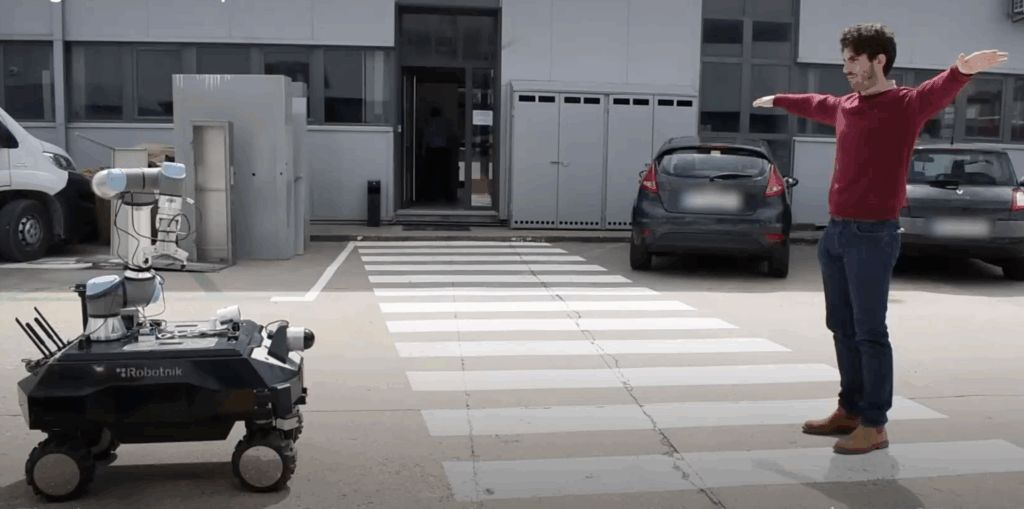

Control of robotic platforms for non-experts

We explore methodologies so that any person can control robots without being a specialist. We design voice, gesture and tele-operation interfaces with controllers or virtual-reality glasses that reduce the learning curve and allow safe operation from day one. Operators can assign tasks, supervise progress and take control when needed, with visual aids like web pages, safety limits and assisted modes.

Typical cases: move a mobile platform to a point with voice instructions or drawings on a map; inspect an area with a tele-operated drone; or train a robotic arm via demonstrations.

Sensors, computing and state-of-the-art hardware for new robotic functions

We continuously invest in finding and researching new alternatives in sensors, computing and emerging hardware to broaden what robots can do under real-world conditions. We select, test and integrate cutting-edge technologies for demanding environments: low visibility, dust, rain, vibration, thermal variations or confined spaces. For example, we combine next-generation 4D radars for detection in fog and snow and synthetic skin with tactile sensors to manipulate fragile objects without damaging them. We add accessories that open new use-cases: haptic grippers with feedback, smart charging stations and industrial communications, Wi-Fi 6/7 and private 5G. Our methodology covers tech scouting, benchmarking, electrical and mechanical integration, and design for maintainability.

RESEARCH PROJECTS

RETECHFOR – Technological and Territorial Network for Forest Monitoring and Environmental Disaster Mitigation as Drivers of the Forest Bioeconomy

We promote the forest bioeconomy in Castilla y León with digital solutions to improve the management, planning, and conservation of resources, generating employment in rural areas.

Duration:

January 2025 – July 2026