Design and manufacture of gas fryer involve thermal simulation to optimize metal thickness and insulation. Discover how efficient design improves performance and durability.

Design and Manufacture of a Gas Fryer

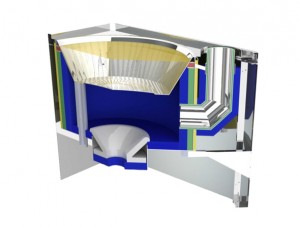

The design and manufacture of gas fryer involve a thorough thermal simulation to ensure optimal performance and durability. This process allows for proper sizing of the metal thickness and insulating materials used, ensuring the fryer operates efficiently and safely.

Thermal Simulation for Optimal Design

Before the actual manufacture, a thermal simulation was conducted. This critical step helps in accurately determining the necessary thickness of the metal and the appropriate insulating materials. By optimizing these components, the fryer achieves better heat retention and energy efficiency.

Benefits of Efficient Gas Fryer Design

Implementing efficient gas fryer´s design results in numerous benefits such as enhanced cooking performance, reduced energy consumption, and extended product lifespan. The careful selection of materials and precise engineering contribute to a high-quality product that meets industry standards.

The project successfully demonstrated the importance of thermal simulation in the design and manufacture of gas. By accurately determining the optimal metal thickness and insulating materials, the project ensured the creation of an efficient and durable product. This approach not only enhanced the fryer’s performance and energy efficiency but also extended its lifespan. The careful integration of advanced design techniques and material selection has resulted in a high-quality gas fryer that meets industry standards and customer expectations. The project’s success underscores the value of precise engineering and thorough testing in producing reliable kitchen equipment.