STC16. Programming and Communication of a Robotic Arm

COURSE DURATION:

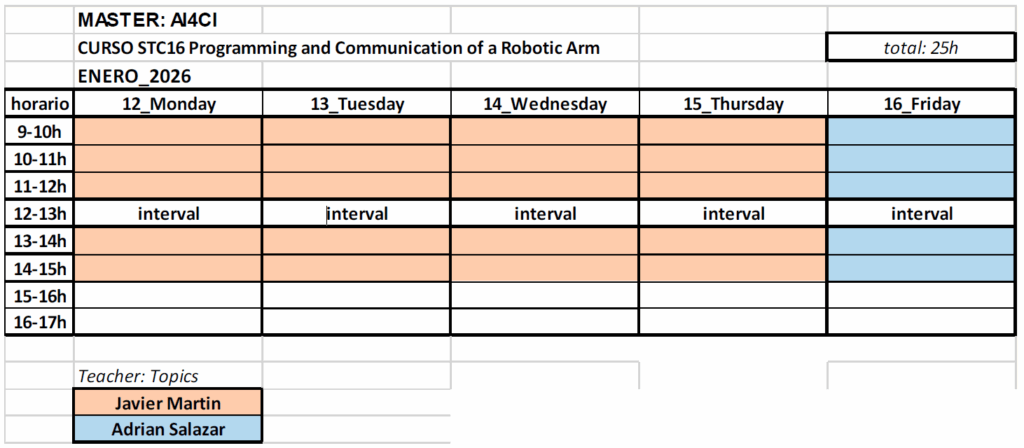

January 12–16, 2026

ECTS CREDITS

3

TIMETABLE:

9:00 to 12:00 and 13:00 to 15:00

MODALITIES:

Online or on-site at ITCL.

This course is part of the European AI4CI Master Artificial Intelligence for Connected Industries.

CORE CONTENT:

Know the mathematical principles that govern the movement of a robot and learn to apply them in simple programs.

Learn to program simple trajectories and correct pre-programmed operations in a robot

Know the different types and levels of communication that a robot has with its environment

Acquire the necessary knowledge to carry out low-level communications with sensorised systems. Learn to carry out communications with PLCs, for example Siemens.

PREREQUISITES:

- Robotics Basics: Having a basic understanding of robotics concepts, such as the kinematics and dynamics of robotic arms, can be beneficial.

- Electronics Fundamentals: Understanding basic electronics concepts such as resistance, voltage, current, and having experience with common electronic components could be essential for working with robotic hardware.

- Having coding experience on Python or C++.

EVALUATION MODALITIES:

- Quizzes and short assimilation tests throughout the course proposed by the teacher.

Value: 50% - A project assignment to perform after the course. Perform individually o in a group.

Value: 50%

CORE CONTENT:

1.Mathematical and Mechanical Principles of Robot Operation

In this section, we will teach you about the main types of articulated robotic arms and their key differences. We will study the primary components of these robots and the mathematical concepts that govern their movement.

2.Communication Languages: Differences in Programming Across Brands

This part will cover the most important communication paradigms used to interface robot controllers with other industrial equipment. We will cover on how robots communicate with their external control systems (PLCs and buses profibus, profinet, opc).

We will discuss their advantages and disadvantages, the types of industries in which they are used, and provide examples.

3.Low-Level Programming

a)Low-Level Programming Controlling a Robotic Arm

In this session, we will focus on controlling a robotic arm using the industrial programming language RAPID, which is used in ABB robots. Participants will learn how to create basic motion routines, define coordinate systems, and interact with the robot’s controller. Additionally, we will explore how to execute point-to-point movements, handle simple input/output signals,

b.Controlling a Robotic Arm with Python and ROS

In this session, we will focus on controlling a robotic arm using the Python programming language. We will translate the knowledge from the first session into Python libraries to control a robotic arm platform in a simulated environment using Gazebo. We will also cover the basics of ROS (Robot Operating System) with robotic arms and compare it with other industrial robotics systems.

CALENDAR:

PEDAGOGICAL OBJECTIVES:

The goal of this STC is to learn the theoretical and practical principles that govern the movement of a robot and how to apply them in simple and programs used in industry. This includes programming simple trajectories in a robotic arm, correcting pre-programmed operations in a robot using frequently used tools in industry—either open-source or brand proprietary—and understanding the different communication strategies that a robot could have with its environment. We will also cover the basic principles of computer vision for robotic arms to perform smart operations with articulated robots.

REQUIRED TEACHING MATERIAL:

The required material in terms of hardware and software will be provided during the course.

CERTIFICATION:

ITCL will issue a certificate indicating the international master’s degree AI4CI – European Master Artificial Intelligence for Connected Industries. On request, 3 ECTS will be awarded by AI4CI partner Ulm University.